Aluminum has long been the “king of lightness” in the world of metals. It is relatively cheap, easy to shape, and suitable for countless applications.

However, when temperatures rise or strength becomes a non-negotiable requirement, aluminum typically gives way to heavier and more expensive materials like titanium or composites.

Now, engineers have announced a new 3-D-printable aluminum alloy. They say it has achieved, in tests, strength five times greater than aluminum made by traditional methods, while maintaining its structure and properties at temperatures up to around 400 degrees Celsius. This brings it a step closer to the toughness of titanium.

The Role of Machine Learning

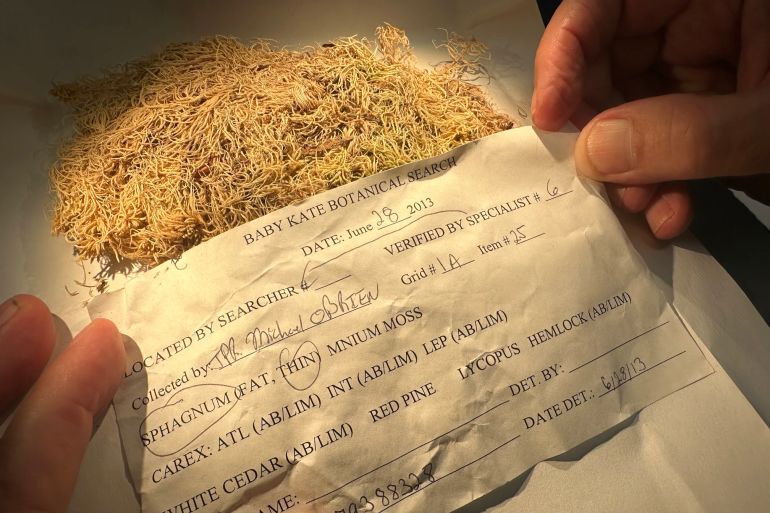

The story is not just about a new “mix of elements,” but a recipe combining two methods: machine learning to quickly select the chemical composition, and laser metal printing to create a very fine internal structure that prevents the usual weakness of aluminum from appearing.

According to the research published in a scientific journal, the machine learning model shortened a path that would have traditionally required examining over a million compositional possibilities. The search was narrowed down to just 40 promising compositions before reaching the optimal one.

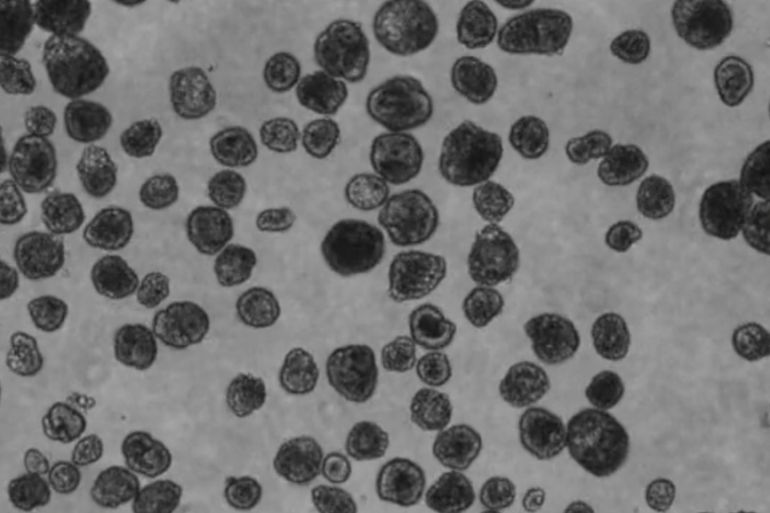

The core idea is that the properties of alloys depend not only on the type of added elements but on the “microscopic engineering” inside the metal, particularly the distribution of very small components called “precipitates.”

The smaller and more closely packed these precipitates are, the harder the metal becomes. However, achieving this structure requires a difficult condition: very rapid cooling that prevents the precipitates from growing and coarsening.

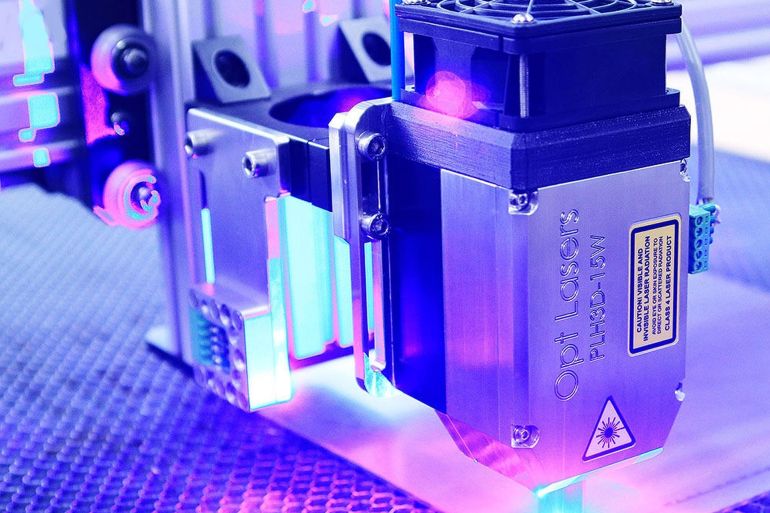

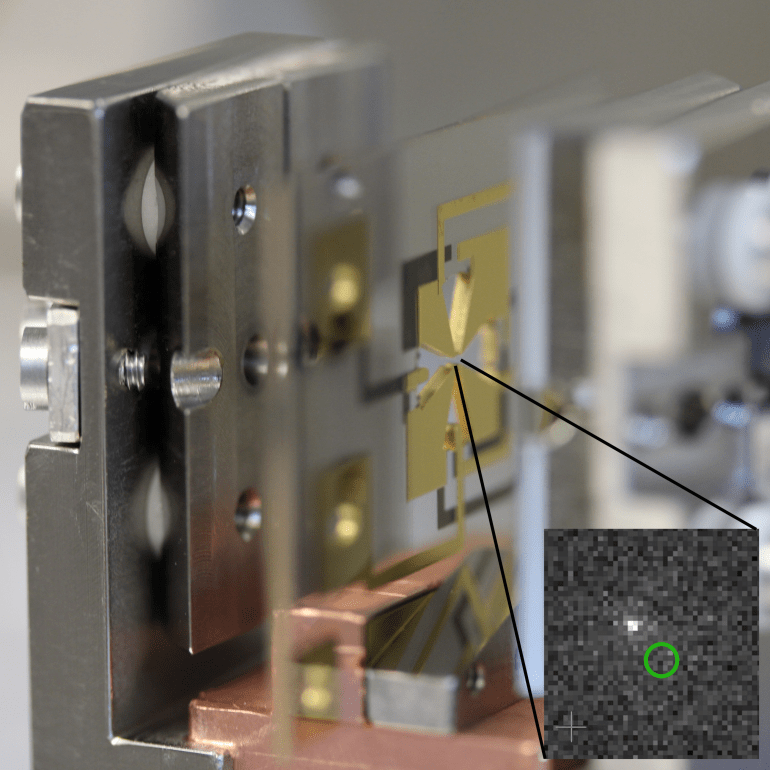

The Laser’s Role

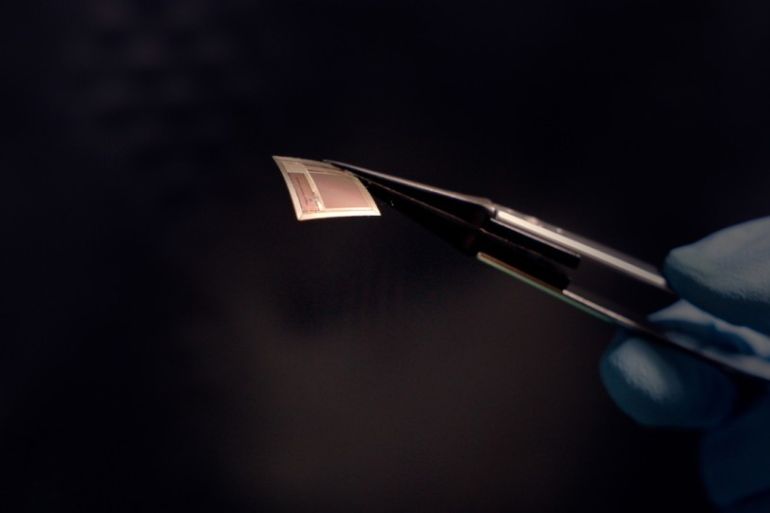

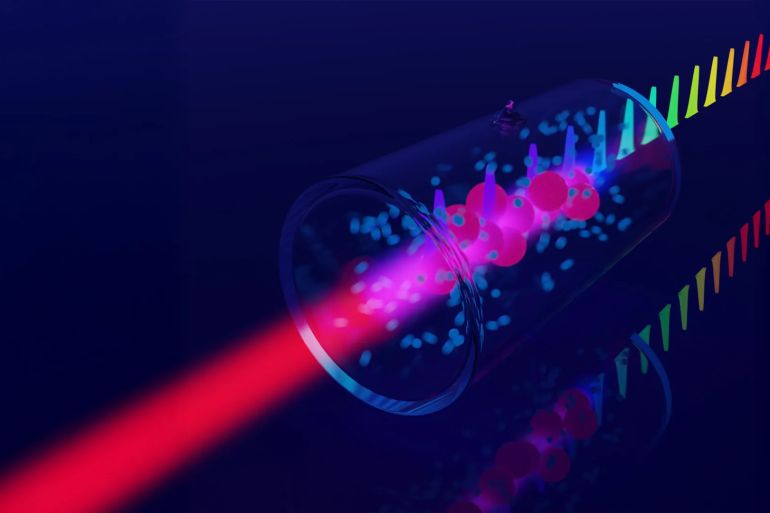

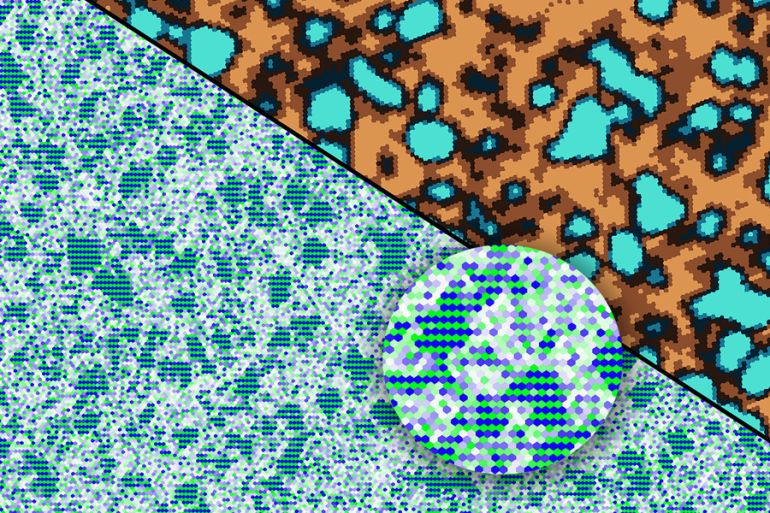

This is where metal printing with “laser powder bed fusion” technology comes in. A laser passes over a thin layer of metal powder, melting it according to the desired shape. It then solidifies rapidly before the next layer is added.

This flash freezing creates a highly precise internal “texture” and locks the nanoscale precipitates in place before they can grow. This high cooling rate is the door opened by 3-D printing, not just for creating complex shapes, but for creating a metal with new properties.

According to the study, the printed samples were five times harder than the cast version of the same alloy and about 50% stronger than alloys designed using traditional simulation without machine learning. The fine microstructure also remained stable up to 400 degrees Celsius.

Promising Applications

This temperature figure is important industrially, because many in the industry look to titanium as the solution when heat and strength are essential conditions, despite it being heavier and more expensive.

Take, for example, jet engine fan blades, which are often made from titanium and can be up to ten times more expensive than aluminum. If part of these components could be replaced with new aluminum alloys, it could impact energy consumption in the transportation sector itself.

The ambition is not limited to aviation. The material’s strength combined with printability could open its use in advanced vacuum pumps,