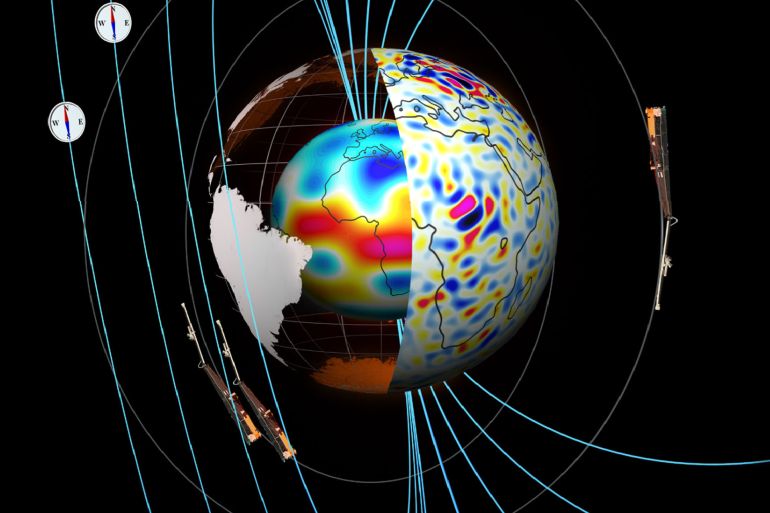

The global demand for critical minerals used in batteries and power grids is increasing with the world’s green transition revolution, but the significant negative impact on the environment poses a real challenge for the future.

Vast areas of forest are cleared daily to extract nickel and cobalt, and land-based ores contain only a very small percentage of required metals like copper, meaning enormous amounts of waste are produced to obtain a small quantity of raw metal.

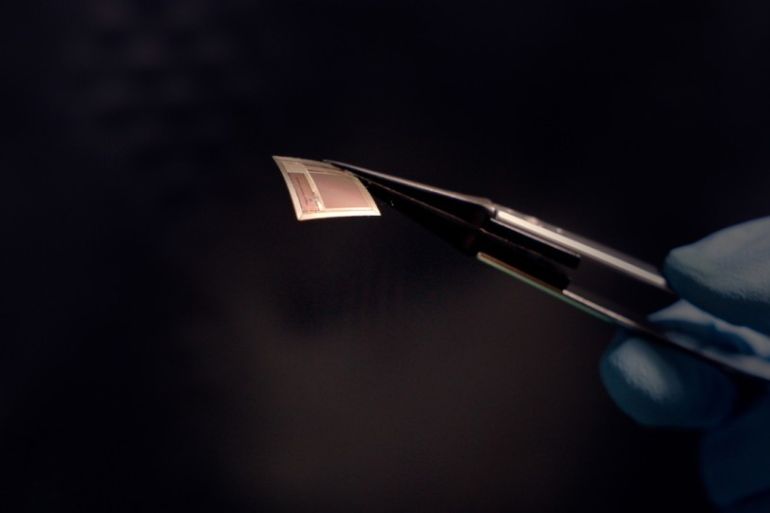

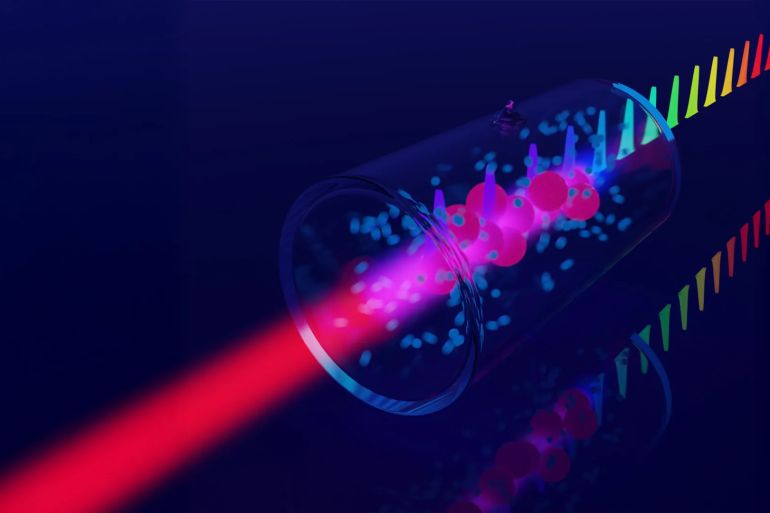

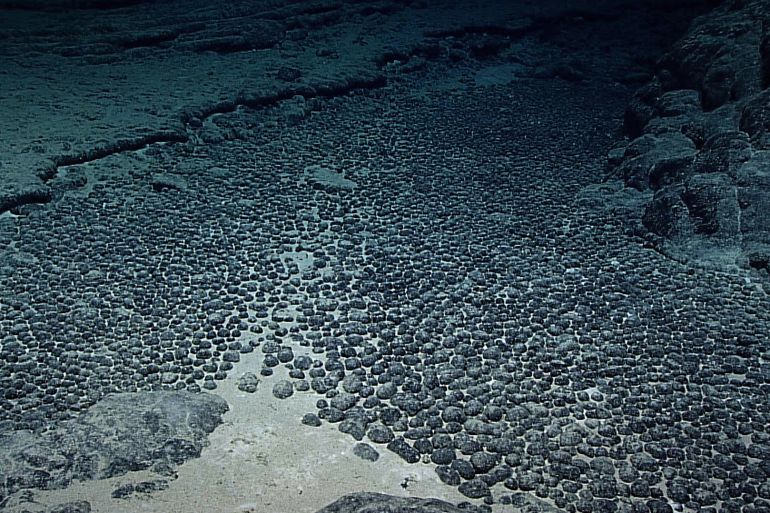

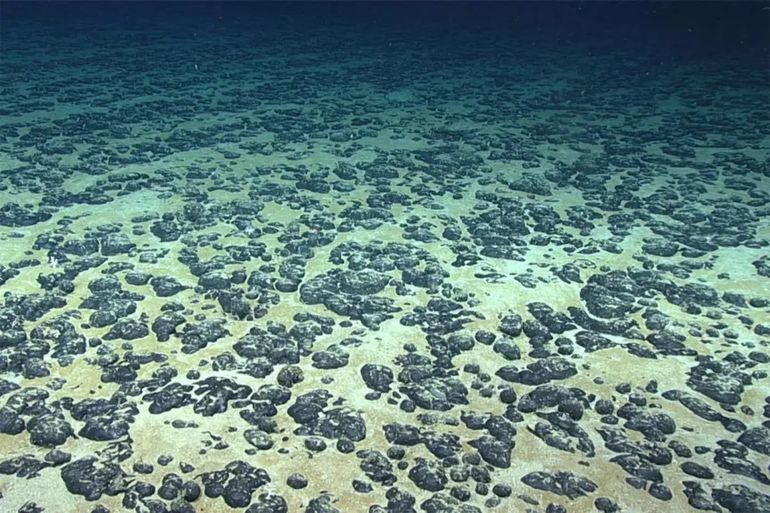

A team of researchers offers an innovative solution that could change the rules of the game in the mining industry by extracting pure copper from deep-sea ores by smelting them in an electric arc furnace, then using hydrogen plasma as a reducing agent instead of coal, resulting in an alloy containing other elements like nickel and cobalt.

In the new experiment, the research team developed a method for extracting metals by smelting marine ores in an electric arc furnace using “hydrogen plasma” as a reducing agent instead of coal, which reduces carbon dioxide emissions and lowers energy consumption.

The process also allows for the separation of pure copper first, followed by the formation of an alloy containing nickel and cobalt, facilitating subsequent processing steps and helping to reduce waste and avoid deforestation often associated with traditional land-based mining.

A Single Sustainable Step

The main scientific innovation lies in developing a fully electric, single-step process for extracting copper, nickel, and cobalt from deep-sea polymetallic nodules.

Unlike current extraction methods, the new method does not rely on carbon-based energy sources or chemical reducing agents like coke or coal.

Traditional methods require multiple stages, including calcination, chemical reduction, and refining, which are energy-intensive processes that produce large amounts of carbon dioxide emissions.

In contrast, the new innovation integrates all these steps into a single electrically powered stage, directly producing a refined metal alloy. As a result, the experiment achieved an estimated 84% reduction in carbon dioxide emissions and an 18% reduction in total energy consumption compared to the latest methods.

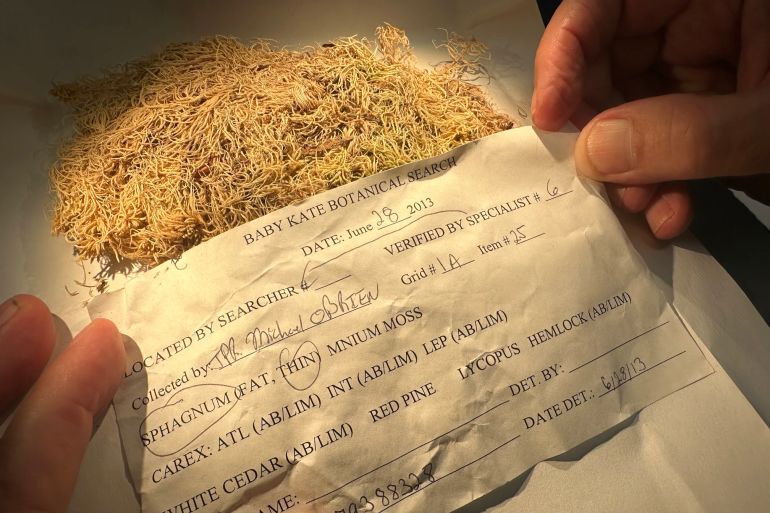

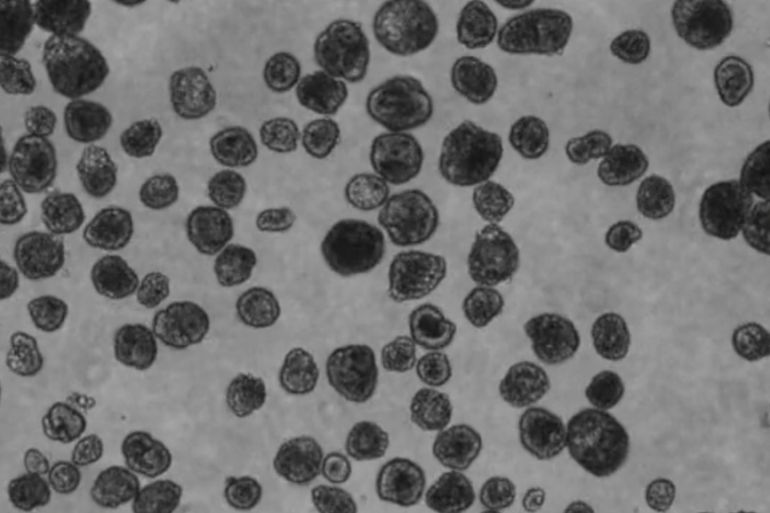

Extracting copper directly without using any external reducing agents is a highly significant achievement. For the first time, copper can be extracted from polymetallic nodules through precise thermodynamic control using a strategy specifically designed for thermal processing. By carefully managing heating and cooling conditions, pure copper can be extracted directly from the nodules.

While the dual use of carbon in traditional metal extraction methods leads to significant carbon dioxide emissions during processing, the hydrogen plasma-based reduction process is supplied with thermal energy from renewable electricity instead of combustion, and carbon-based reducing agents are replaced with hydrogen.

Consequently, oxygen is removed from metal oxides via hydrogen reduction, producing water vapor as the main byproduct instead of significant greenhouse gas emissions, while also improving the reported energy efficiency. This highlights the environmental advantages of this pathway for sustainably extracting vital minerals.

Environmental Considerations

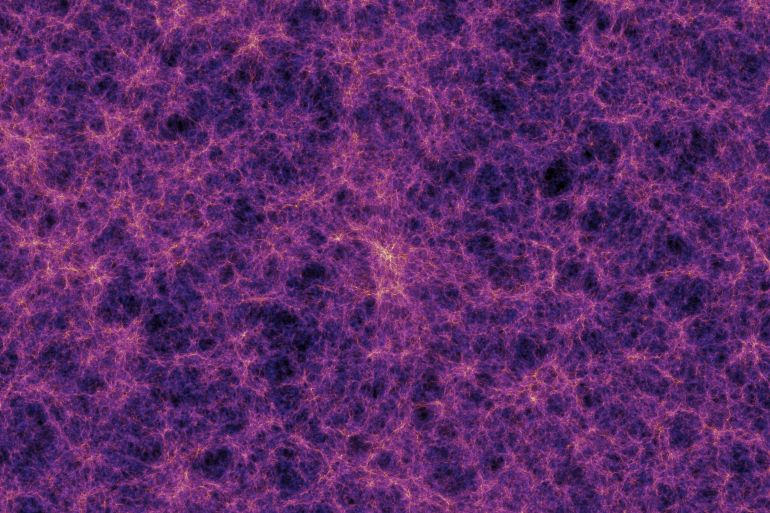

Large-scale extraction of polymetallic nodules from the deep sea presents an environmental challenge that must be addressed. These nodules exist in some of the least explored ecosystems on Earth, and large-scale disturbance of the seabed could affect deep-ocean habitats, disrupt slow-growing biological balances, and alter sediment structure.

Additional concerns include the formation of sediment plumes, potential impacts on mid-water ecosystems, uncertainties surrounding long-term recovery, and loss of biodiversity.

The key challenges lie in the insufficient understanding of many of these ecological impacts due to limited data, and the cumulative and long-term nature of the consequences of deep-sea mining, which may only become apparent over extended periods. This underscores the importance of a precautionary approach and conducting thorough scientific